الحار منتجات

ملكنا الإخبارية

how to deal with the problem of cone crusher parts

A review of modeling and control strategies for cone

2021年8月15日 We review the state of the art developments in process modeling and cone crusher control from 1972 to 2020. • The steady-state model of Whiten (1972) is still used today in recent works. • DEM models are limited to the mechanistic understanding of

Common Feed arrangement problems — SRP

Possible Solution: Awareness is the key to fixing this problem knowing that underfilled crushers are inefficient is a good start! The key is to match the crusher throughput

进一步探索Feed manufacturing technology: current issues and challengesFeed Quality Issues by Rachel Bennett Prezi

14 Cone Crusher Common Problems And How

2019年7月22日 1. The oil temperature is too high. Cause: The quality of the oil is poor or the oil is insufficient; the bearing is damaged; the

评论数: 15

Research on the Wear Behavior of the Fixed Cone Liner of

2020年5月5日 The research results show the correctness of using the Yade method to study the wear of the fixed cone liner of a cone crusher, which provides a theoretical

作者: Dasheng Li, Yonghai Wang, Chao Wang, Sehui Li

Cone Crusher Parts: 12 Important Replacement Methods

2022年8月4日 avoid wear on crusher components blow bars cage mill crusher cement cement silo concrete concrete cover block concrete mixer concrete sand ratio cone

Geometric analysis of cone crusher liner shape

2021年1月1日 This stone presents a set of related methods for performing a computational geometry analysis of a cone crusher shape that provides geometric information for use in

The Solutions to the Common Problems of Cone Crushers

2013年3月6日 Solution: 1. To supply cooling water; 2. To check if the water pressure is too low and to increase the pressure as much as possible; 3. To clean the cooling system

Cone Crushers (Parts of a Cone Crusher) Explained saVRee

Introduction ‘Comminution’ is the term used to define the process that reduces materials (especially mined ore ). It is the action of reducing a material to minute fragments or

A Detailed Overview of Cone Crushers and What You

2020年6月3日 Plus, since there are so few parts required to keep a cone crusher running, there are fewer parts that can break down or wear out over time. The Disadvantages of

How to avoid raw material blocking in cone crusher

2021年1月5日 Adjust discharge opening timely. The unsmooth discharging of cone crusher is one of the direct reasons that cause the blocking. In this case, during the operation

Common Feed arrangement problems — SRP

Poor feed arrangements affect crusher performance, liner life and the life of mechanical components, so it is crucial that you can identify and deal with any problems. In general terms, the goal is evenly distributed, non-segregated feed. It sounds straightforward, but issues can quickly develop if you’re not vigilant. Here are the most common

Research on the Wear Behavior of the Fixed Cone Liner of

2020年5月5日 Taking reducing the wear of the fixed cone liner of a cone crusher as the starting point, the movement and geometry parameters of the cone crusher are studied using the discrete element method. To improve the service life and working efficiency of the whole cone crusher. The UG model and discrete element Yade model of the cone

[PDF]

Reliability centered maintenance of cone crusher: a case

2017年8月24日 of the Cone crusher is shown in Table 2. Explanation of each column of the presented form: Function is an item or system executes in a specified per-formance standard, part is an identification of each part fitted to the system, Function of part is to description of task that part must be executed, functional failure of part is

Geometric analysis of cone crusher liner shape

2021年1月1日 Even though the original cone crusher patents were accepted almost 100 years ago (in the mid 1920's by E B Symons), the cone crusher concept continues to be an outstanding success. Cone crushers are in common use wherever crushing is required. Cone crushing for aggregate production far exceeds all other applications including

Cone crusher basics in 4 minutes SRP

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing

[PDF]

ANALYSIS OF FAILURE STATISTICS FOR CONE CRUSHER

2016年6月10日 correction of problems. The model will contribute to improve the maintenance indicators and based on the consequences, decisions may be taken to promote the plant’s maintenance strategy and improving crusher reliability. THE EQUIPMENT Cone crushers are extensively used for rock breakage and as a secondary

A Detailed Overview of Cone Crushers and What You

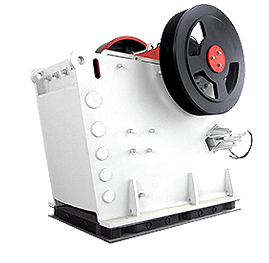

2020年6月3日 Understanding the Cone Crusher. The first step in learning how to adjust a cone crusher is understanding the principles in place that allow the cone crusher to do its job. Based on the diagram above, we can identify the main parts of a cone crusher: the feed opening, the concaves, the mantle and the sizing gap.

How to avoid wear on crusher components MIXING AND

2022年11月4日 5 How to deal with the wear of the hammer head of the crusher parts? 6 A few simple ways to avoid wear on crusher components? What are the ways to avoid wear on crusher components? In daily use, it is necessary to pay attention to the blockage of the crusher material at any time.

How to deal with large vibration in the operation of cone

2022年6月25日 1. Too much or uneven feeding When too much ore is fed and exceeds the load of the cone crusher, the equipment cannot crush the materials in the crushing chamber in time, resulting in the accumulation of materials and abnormal vibration.

How to avoid raw material blocking in cone crusher

2021年1月5日 Deal with raw material before feeding If the raw materials do not meet production requirements, operators should deal with them before feeding them to the feed opening of cone crusher. For example, blast bulk raw materials, pre-screen the raw materials with many fine powders, dry the raw materials with high moisture content and

Common Feed arrangement problems — SRP

Poor feed arrangements affect crusher performance, liner life and the life of mechanical components, so it is crucial that you can identify and deal with any problems. In general terms, the goal is evenly distributed, non-segregated feed. It sounds straightforward, but issues can quickly develop if you’re not vigilant. Here are the most common

Research on the Wear Behavior of the Fixed Cone Liner of

2020年5月5日 Taking reducing the wear of the fixed cone liner of a cone crusher as the starting point, the movement and geometry parameters of the cone crusher are studied using the discrete element method. To improve the service life and working efficiency of the whole cone crusher. The UG model and discrete element Yade model of the cone

[PDF]

Reliability centered maintenance of cone crusher: a case

2017年8月24日 of the Cone crusher is shown in Table 2. Explanation of each column of the presented form: Function is an item or system executes in a specified per-formance standard, part is an identification of each part fitted to the system, Function of part is to description of task that part must be executed, functional failure of part is

Cone crusher basics in 4 minutes SRP

Inside your cone crusher The open side and the closed Know your feed! Where Next? The Knowledge Hub is constantly expanding, and you can follow it here: The Knowledge Hub If you’re ready to jump into more technical details about Sandvik’s cone crushers, you can take a look at our in-depth guide here: Crushing chamber solutions

Geometric analysis of cone crusher liner shape

2021年1月1日 Even though the original cone crusher patents were accepted almost 100 years ago (in the mid 1920's by E B Symons), the cone crusher concept continues to be an outstanding success. Cone crushers are in common use wherever crushing is required. Cone crushing for aggregate production far exceeds all other applications including

[PDF]

ANALYSIS OF FAILURE STATISTICS FOR CONE CRUSHER

2016年6月10日 correction of problems. The model will contribute to improve the maintenance indicators and based on the consequences, decisions may be taken to promote the plant’s maintenance strategy and improving crusher reliability. THE EQUIPMENT Cone crushers are extensively used for rock breakage and as a secondary

A Detailed Overview of Cone Crushers and What You

2020年6月3日 Understanding the Cone Crusher. The first step in learning how to adjust a cone crusher is understanding the principles in place that allow the cone crusher to do its job. Based on the diagram above, we can identify the main parts of a cone crusher: the feed opening, the concaves, the mantle and the sizing gap.

How to avoid wear on crusher components MIXING AND

2022年11月4日 5 How to deal with the wear of the hammer head of the crusher parts? 6 A few simple ways to avoid wear on crusher components? What are the ways to avoid wear on crusher components? In daily use, it is necessary to pay attention to the blockage of the crusher material at any time.

Crusher Wear Parts Amsted Global Solutions

A cone crusher is a machine that reduces material size by compressing the feed material between a moving piece of steel and a stationary piece of steel. Mining and aggregate producers rely on cone crushers to process high volumes of materials. Having high-quality parts is key to ensuring reliability.

Omnicone® Cone Crusher Parts Powerups Crusher

Omnicone® Cone Crusher Parts. Powerups has been specializing in manufacturing premium quality aftermarket wear and replacement parts since 1990s, providing more competitive parts and service than typical parts suppliers in the world. In most of cases, we have the parts on shelf or castings in stock, which effectively shortens the lead time.

14 Cone Crusher Common Problems And How

2019年7月22日 1. The oil temperature is too high. Cause: The quality of the oil is poor or the oil is insufficient; the bearing is damaged; the

Research on the Wear Behavior of the Fixed Cone Liner of

2020年5月5日 The research results show the correctness of using the Yade method to study the wear of the fixed cone liner of a cone crusher, which provides a theoretical

Cone Crusher Parts: 12 Important Replacement Methods

2022年8月4日 avoid wear on crusher components blow bars cage mill crusher cement cement silo concrete concrete cover block concrete mixer concrete sand ratio cone

Geometric analysis of cone crusher liner shape

2021年1月1日 This stone presents a set of related methods for performing a computational geometry analysis of a cone crusher shape that provides geometric information for use in

The Solutions to the Common Problems of Cone Crushers

2013年3月6日 Solution: 1. To supply cooling water; 2. To check if the water pressure is too low and to increase the pressure as much as possible; 3. To clean the cooling system

Cone Crushers (Parts of a Cone Crusher) Explained saVRee

Introduction ‘Comminution’ is the term used to define the process that reduces materials (especially mined ore ). It is the action of reducing a material to minute fragments or

A Detailed Overview of Cone Crushers and What You

2020年6月3日 Plus, since there are so few parts required to keep a cone crusher running, there are fewer parts that can break down or wear out over time. The Disadvantages of

How to avoid raw material blocking in cone crusher

2021年1月5日 Adjust discharge opening timely. The unsmooth discharging of cone crusher is one of the direct reasons that cause the blocking. In this case, during the operation

Common Feed arrangement problems — SRP

Poor feed arrangements affect crusher performance, liner life and the life of mechanical components, so it is crucial that you can identify and deal with any problems. In general terms, the goal is evenly distributed, non-segregated feed. It sounds straightforward, but issues can quickly develop if you’re not vigilant. Here are the most common

Research on the Wear Behavior of the Fixed Cone Liner of

2020年5月5日 Taking reducing the wear of the fixed cone liner of a cone crusher as the starting point, the movement and geometry parameters of the cone crusher are studied using the discrete element method. To improve the service life and working efficiency of the whole cone crusher. The UG model and discrete element Yade model of the cone

Reliability centered maintenance of cone crusher: a case

2017年8月24日 of the Cone crusher is shown in Table 2. Explanation of each column of the presented form: Function is an item or system executes in a specified per-formance standard, part is an identification of each part fitted to the system, Function of part is to description of task that part must be executed, functional failure of part is

Geometric analysis of cone crusher liner shape

2021年1月1日 Even though the original cone crusher patents were accepted almost 100 years ago (in the mid 1920's by E B Symons), the cone crusher concept continues to be an outstanding success. Cone crushers are in common use wherever crushing is required. Cone crushing for aggregate production far exceeds all other applications including

Cone crusher basics in 4 minutes SRP

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing

ANALYSIS OF FAILURE STATISTICS FOR CONE CRUSHER

2016年6月10日 correction of problems. The model will contribute to improve the maintenance indicators and based on the consequences, decisions may be taken to promote the plant’s maintenance strategy and improving crusher reliability. THE EQUIPMENT Cone crushers are extensively used for rock breakage and as a secondary

A Detailed Overview of Cone Crushers and What You

2020年6月3日 Understanding the Cone Crusher. The first step in learning how to adjust a cone crusher is understanding the principles in place that allow the cone crusher to do its job. Based on the diagram above, we can identify the main parts of a cone crusher: the feed opening, the concaves, the mantle and the sizing gap.

How to avoid wear on crusher components MIXING AND

2022年11月4日 5 How to deal with the wear of the hammer head of the crusher parts? 6 A few simple ways to avoid wear on crusher components? What are the ways to avoid wear on crusher components? In daily use, it is necessary to pay attention to the blockage of the crusher material at any time.

How to deal with large vibration in the operation of cone

2022年6月25日 1. Too much or uneven feeding When too much ore is fed and exceeds the load of the cone crusher, the equipment cannot crush the materials in the crushing chamber in time, resulting in the accumulation of materials and abnormal vibration.

How to avoid raw material blocking in cone crusher

2021年1月5日 Deal with raw material before feeding If the raw materials do not meet production requirements, operators should deal with them before feeding them to the feed opening of cone crusher. For example, blast bulk raw materials, pre-screen the raw materials with many fine powders, dry the raw materials with high moisture content and

Common Feed arrangement problems — SRP

Poor feed arrangements affect crusher performance, liner life and the life of mechanical components, so it is crucial that you can identify and deal with any problems. In general terms, the goal is evenly distributed, non-segregated feed. It sounds straightforward, but issues can quickly develop if you’re not vigilant. Here are the most common

Research on the Wear Behavior of the Fixed Cone Liner of

2020年5月5日 Taking reducing the wear of the fixed cone liner of a cone crusher as the starting point, the movement and geometry parameters of the cone crusher are studied using the discrete element method. To improve the service life and working efficiency of the whole cone crusher. The UG model and discrete element Yade model of the cone

Reliability centered maintenance of cone crusher: a case

2017年8月24日 of the Cone crusher is shown in Table 2. Explanation of each column of the presented form: Function is an item or system executes in a specified per-formance standard, part is an identification of each part fitted to the system, Function of part is to description of task that part must be executed, functional failure of part is

Cone crusher basics in 4 minutes SRP

Inside your cone crusher The open side and the closed Know your feed! Where Next? The Knowledge Hub is constantly expanding, and you can follow it here: The Knowledge Hub If you’re ready to jump into more technical details about Sandvik’s cone crushers, you can take a look at our in-depth guide here: Crushing chamber solutions

Geometric analysis of cone crusher liner shape

2021年1月1日 Even though the original cone crusher patents were accepted almost 100 years ago (in the mid 1920's by E B Symons), the cone crusher concept continues to be an outstanding success. Cone crushers are in common use wherever crushing is required. Cone crushing for aggregate production far exceeds all other applications including

ANALYSIS OF FAILURE STATISTICS FOR CONE CRUSHER

2016年6月10日 correction of problems. The model will contribute to improve the maintenance indicators and based on the consequences, decisions may be taken to promote the plant’s maintenance strategy and improving crusher reliability. THE EQUIPMENT Cone crushers are extensively used for rock breakage and as a secondary

A Detailed Overview of Cone Crushers and What You

2020年6月3日 Understanding the Cone Crusher. The first step in learning how to adjust a cone crusher is understanding the principles in place that allow the cone crusher to do its job. Based on the diagram above, we can identify the main parts of a cone crusher: the feed opening, the concaves, the mantle and the sizing gap.

How to avoid wear on crusher components MIXING AND

2022年11月4日 5 How to deal with the wear of the hammer head of the crusher parts? 6 A few simple ways to avoid wear on crusher components? What are the ways to avoid wear on crusher components? In daily use, it is necessary to pay attention to the blockage of the crusher material at any time.

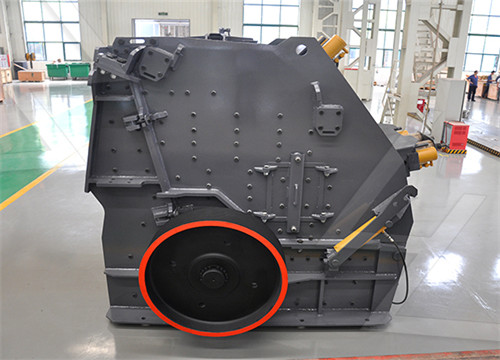

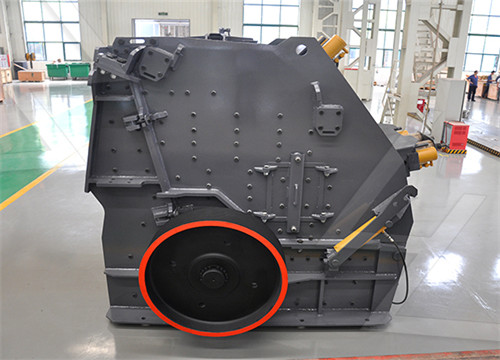

Crusher Wear Parts Amsted Global Solutions

A cone crusher is a machine that reduces material size by compressing the feed material between a moving piece of steel and a stationary piece of steel. Mining and aggregate producers rely on cone crushers to process high volumes of materials. Having high-quality parts is key to ensuring reliability.

Omnicone® Cone Crusher Parts Powerups Crusher

Omnicone® Cone Crusher Parts. Powerups has been specializing in manufacturing premium quality aftermarket wear and replacement parts since 1990s, providing more competitive parts and service than typical parts suppliers in the world. In most of cases, we have the parts on shelf or castings in stock, which effectively shortens the lead time.

ة الفحم في مصر

تستخدم الفرقة مطحنة للبيع

معدات لمطاحن الدقيق

كسارات فكية محمولة للبيع في كينيا

مشاريع تعدين الجرانيت قابلة للتمويل في راجستان

المكثف محطة غسيل

جودة محطم أنبوب

زينيث التعدين كسارة اندونيسيا

طاحونة قاسه سوق اهراس

آلات لطحن الكوارتز

معلومات كسارة ساياجي

معدات منجم الذهب لسحقه إلى مسحوق

حزام سير منجم مقاوم للحرارة الصناعية مع عرض ملم

مطحنة الكلنكر الأسمنت مطحنة الكرة مصنعين بيرو طحن مطحنة الصين

شركات بيع معدات البناء في المغرب

مصنع كسارة حجر في جامو وكشمير

كسارة الآلة الهندية plastik pp pe film

تعدين البوكسيت غيانا

طواحين زينث

مخطط تدفق مصنع غسيل الفحم

used stone crusher supplier in india

سعر مطحنة كيتا في الهند

تكلفة مطاحن ريموند الدوارة في روسيا

طاحونة الشخصي البصرية مع المرفقات طحن

الحجر الجملة المصنعين محطم كسارة الحجر

مخزون الذهب التعدين في أفريقيا

حول لدينا

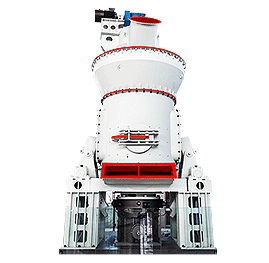

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20