الحار منتجات

ملكنا الإخبارية

the crushed ore is collected from the ore crushing plants

Iron processing Ores, Surface Mining, Sintering, and

Crushed ore is divided into various fractions by passing it over sieves through which undersized material falls. In this way, lump or rubble ore (7 to 25 millimetres in size) is

Crusher an overview ScienceDirect Topics

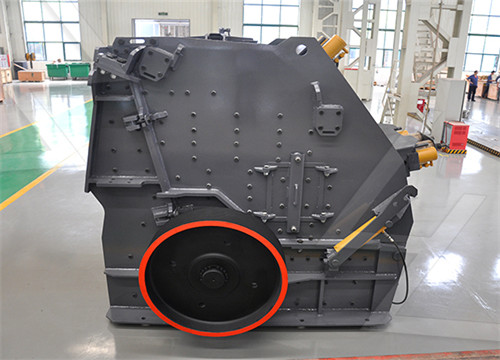

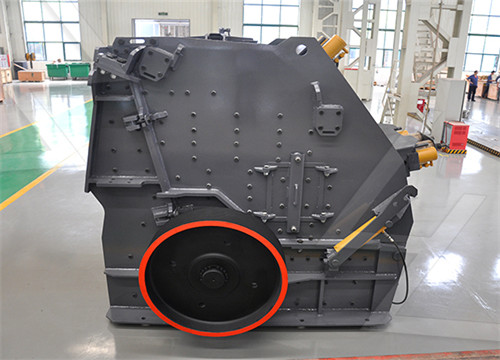

Crushing is accomplished by compression of the ore against a rigid surface or by impact against a surface in a rigidly constrained motion path. Crushing is usually a dry process

进一步探索5 Types Of Stone Crushers Application and MaintenanceTypes of Crushers Mineral ProcessingMetallurgy

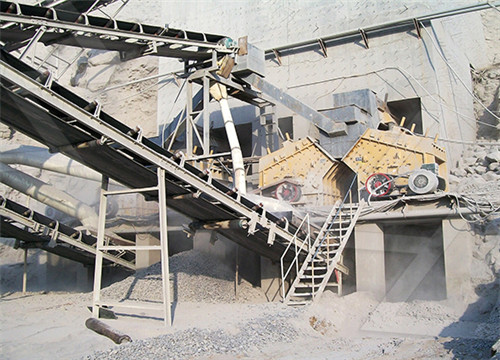

Crushing Plant an overview ScienceDirect Topics

A crushing plant delivered ore to a wet grinding mill for further size reduction. The size of crushed ore (F 80) was. 4.0 mm and the S.G. 2.8 t/m 3. The work index of the ore was

OPP: Ore Preparation Plants Explained Oil Sands Magazine

2016年4月24日 The Ore Preparation Plant (OPP) is the first step within any Bitumen Production facility where mined oil sands is loosely crushed and mixed with hot/warm

What is the waste from an ore-crushing plant? LinkedIn

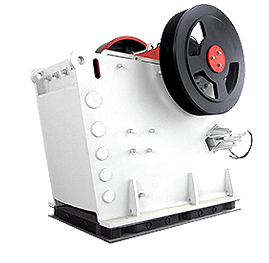

2023年3月30日 The waste from an ore-crushing plant can include crushed rock, soil, dust, and other material that is produced during the process of crushing the ore. Jaw crusher

Distribution of types of ore crushed according to ore

Since the crushing plants are operated under severe conditions and subjected to very abrasive material, several factors can influence Conditioning (Psychology)

[PDF]

Crushing Plant Design and Layout Considerations 911

2016年2月24日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production

Crushing and Grinding WetSticky Ore 911

2016年5月9日 In the flowsheet illustrated the basic steps are shown for the average mill. Primary slimes are treated separately, while the washed and crushed ore is ground, classified, and floated in the usual manner. This

The Crushed Ore Is Collected From The Ore Crushing

2021年9月16日 A crushing plant delivered ore to a wet grinding mill for further size reduction the size of crushed ore f 80 was 40 mm and the sg 28 tm 3 the work index of

[PDF]

Lead and Zinc Department of Energy

2013年11月8日 the mine site, followed by additional crushing at the mill. The crushed ore is mixed with water and initial flotation reagents to form slurry. The ore is then ground in rod and ball mills. The slurry may also be ground in autogenous mills (a mill where the ore acts as the grinding medium) or semi-autogenous mills (steel balls are added to the ore).

Crusher an overview ScienceDirect Topics

Cone crushers were originally designed and developed by Symons around 1920 and therefore are often described as Symons cone crushers.

[PDF]

The environmental impact of gold mines: pollution by

2.1. Crushing The ore is stockpiled and the process begins by feeding the ore into a hopper with a loader. The ore is then drawn via a variable speed hydraulically driven belt feeder and delivered to the crusher. Crushing is carried out in a jaw crusher. Crushed ore is conveyed directly into the ball mill. 2.2. Grinding and sizing

OPP: Ore Preparation Plants Explained Oil Sands Magazine

2016年4月24日 The crushed ore is dumped onto conveyors, which transport the loose oil sands to a storage pile or surge bin. Since the oil sands ore is mined out of a pit (or hole in the ground), the crushing plant is normally also installed at a lower elevation, or in-pit. This helps minimize elevation changes for the haul trucks.

(PDF) SIZE REDUCTION BY CRUSHING

2017年3月4日 Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by...

Technology improvements of crushing process in

1996年3月1日 1. Introduction Based on detailed laboratory and industrial research, Majdanpek Copper Mine makes the reconstruction and the modernization of crushing plant in order to create the adequate conditions for profitable business. Studying the operation efficiency of each crusher, numerous investigations are made.

(PDF) Comminution in mineral processing ResearchGate

2018年11月19日 Technische Universität Clausthal Abstract and Figures The aim of mineral processing is to get the mineral from rock or Ore that has good economic value in the market. Generally, the ability of...

Mining and processing plant engineering design ESFC

2022年8月14日 The obvious advantage of this equipment is the fine, uniform crushing of the ore. The disadvantages of the disintegrator include the rapid wear of pins, the difficulty of replacing them and the need for accurate balancing of the rotating parts of the machine. Engineering design of grinding equipment After the crushing process, the ore is ground.

[PDF]

Crushing Plant Design and Layout Considerations 911

2016年2月24日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of parties.

Major MinesProjects Veladero Mine

Ore that has a gold grade above the cut-off grade for crushed ore is trucked from the mine or stockpiles and crushed in one of two two-stage crushing circuits to a nominal size of 80% passing (P80) 40 mm. The crushed ore is hauled by a fleet of 11 trucks from the crushing plant to the VLF, a distance of approximately 4.2 km.

[PDF]

Lead and Zinc Department of Energy

2013年11月8日 the mine site, followed by additional crushing at the mill. The crushed ore is mixed with water and initial flotation reagents to form slurry. The ore is then ground in rod and ball mills. The slurry may also be ground in autogenous mills (a mill where the ore acts as the grinding medium) or semi-autogenous mills (steel balls are added to the ore).

(PDF) Overview of Mineral Processing Methods

2015年8月3日 Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals. It is done in order to produce a concentrate containing most of the ore minerals and a

[PDF]

The environmental impact of gold mines: pollution by

2.1. Crushing The ore is stockpiled and the process begins by feeding the ore into a hopper with a loader. The ore is then drawn via a variable speed hydraulically driven belt feeder and delivered to the crusher. Crushing is carried out in a jaw crusher. Crushed ore is conveyed directly into the ball mill. 2.2. Grinding and sizing

OPP: Ore Preparation Plants Explained Oil Sands Magazine

2016年4月24日 The crushed ore is dumped onto conveyors, which transport the loose oil sands to a storage pile or surge bin. Since the oil sands ore is mined out of a pit (or hole in the ground), the crushing plant is normally also installed at a lower elevation, or in-pit. This helps minimize elevation changes for the haul trucks.

(PDF) SIZE REDUCTION BY CRUSHING

2017年3月4日 Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by...

Technology improvements of crushing process in

1996年3月1日 1. Introduction Based on detailed laboratory and industrial research, Majdanpek Copper Mine makes the reconstruction and the modernization of crushing plant in order to create the adequate conditions for profitable business. Studying the operation efficiency of each crusher, numerous investigations are made.

[PDF]

11.24 Metallic Minerals Processing US EPA

2015年9月10日 Metallic mineral processing typically involves the mining of ore from either open pit orunderground mines; the crushing and grinding of ore; the separation of valuable minerals from matrixrock through various concentration steps; and at some operations, the drying, calcining, or pelletizingof concentrates to ease further handling and refining.

Mining and processing plant engineering design ESFC

2022年8月14日 The obvious advantage of this equipment is the fine, uniform crushing of the ore. The disadvantages of the disintegrator include the rapid wear of pins, the difficulty of replacing them and the need for accurate balancing of the rotating parts of the machine. Engineering design of grinding equipment After the crushing process, the ore is ground.

Major MinesProjects Veladero Mine

Ore that has a gold grade above the cut-off grade for crushed ore is trucked from the mine or stockpiles and crushed in one of two two-stage crushing circuits to a nominal size of 80% passing (P80) 40 mm. The crushed ore is hauled by a fleet of 11 trucks from the crushing plant to the VLF, a distance of approximately 4.2 km.

Crushing Plant an overview ScienceDirect Topics

A crushing plant delivered ore to a wet grinding mill for further size reduction. The size of crushed ore (F 80) was. 4.0 mm and the S.G. 2.8 t/m 3. The work index of the ore was

OPP: Ore Preparation Plants Explained Oil Sands Magazine

2016年4月24日 The Ore Preparation Plant (OPP) is the first step within any Bitumen Production facility where mined oil sands is loosely crushed and mixed with hot/warm

What is the waste from an ore-crushing plant? LinkedIn

2023年3月30日 The waste from an ore-crushing plant can include crushed rock, soil, dust, and other material that is produced during the process of crushing the ore. Jaw crusher

Distribution of types of ore crushed according to ore

Since the crushing plants are operated under severe conditions and subjected to very abrasive material, several factors can influence Conditioning (Psychology)

Crushing Plant Design and Layout Considerations 911

2016年2月24日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production

Crushing and Grinding WetSticky Ore 911

2016年5月9日 In the flowsheet illustrated the basic steps are shown for the average mill. Primary slimes are treated separately, while the washed and crushed ore is ground, classified, and floated in the usual manner. This

The Crushed Ore Is Collected From The Ore Crushing

2021年9月16日 A crushing plant delivered ore to a wet grinding mill for further size reduction the size of crushed ore f 80 was 40 mm and the sg 28 tm 3 the work index of

Lead and Zinc Department of Energy

2013年11月8日 the mine site, followed by additional crushing at the mill. The crushed ore is mixed with water and initial flotation reagents to form slurry. The ore is then ground in rod and ball mills. The slurry may also be ground in autogenous mills (a mill where the ore acts as the grinding medium) or semi-autogenous mills (steel balls are added to the ore).

Crusher an overview ScienceDirect Topics

Cone crushers were originally designed and developed by Symons around 1920 and therefore are often described as Symons cone crushers.

The environmental impact of gold mines: pollution by

2.1. Crushing The ore is stockpiled and the process begins by feeding the ore into a hopper with a loader. The ore is then drawn via a variable speed hydraulically driven belt feeder and delivered to the crusher. Crushing is carried out in a jaw crusher. Crushed ore is conveyed directly into the ball mill. 2.2. Grinding and sizing

OPP: Ore Preparation Plants Explained Oil Sands Magazine

2016年4月24日 The crushed ore is dumped onto conveyors, which transport the loose oil sands to a storage pile or surge bin. Since the oil sands ore is mined out of a pit (or hole in the ground), the crushing plant is normally also installed at a lower elevation, or in-pit. This helps minimize elevation changes for the haul trucks.

(PDF) SIZE REDUCTION BY CRUSHING

2017年3月4日 Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by...

Technology improvements of crushing process in

1996年3月1日 1. Introduction Based on detailed laboratory and industrial research, Majdanpek Copper Mine makes the reconstruction and the modernization of crushing plant in order to create the adequate conditions for profitable business. Studying the operation efficiency of each crusher, numerous investigations are made.

(PDF) Comminution in mineral processing ResearchGate

2018年11月19日 Technische Universität Clausthal Abstract and Figures The aim of mineral processing is to get the mineral from rock or Ore that has good economic value in the market. Generally, the ability of...

Mining and processing plant engineering design ESFC

2022年8月14日 The obvious advantage of this equipment is the fine, uniform crushing of the ore. The disadvantages of the disintegrator include the rapid wear of pins, the difficulty of replacing them and the need for accurate balancing of the rotating parts of the machine. Engineering design of grinding equipment After the crushing process, the ore is ground.

Crushing Plant Design and Layout Considerations 911

2016年2月24日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of parties.

Major MinesProjects Veladero Mine

Ore that has a gold grade above the cut-off grade for crushed ore is trucked from the mine or stockpiles and crushed in one of two two-stage crushing circuits to a nominal size of 80% passing (P80) 40 mm. The crushed ore is hauled by a fleet of 11 trucks from the crushing plant to the VLF, a distance of approximately 4.2 km.

Lead and Zinc Department of Energy

2013年11月8日 the mine site, followed by additional crushing at the mill. The crushed ore is mixed with water and initial flotation reagents to form slurry. The ore is then ground in rod and ball mills. The slurry may also be ground in autogenous mills (a mill where the ore acts as the grinding medium) or semi-autogenous mills (steel balls are added to the ore).

(PDF) Overview of Mineral Processing Methods

2015年8月3日 Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals. It is done in order to produce a concentrate containing most of the ore minerals and a

The environmental impact of gold mines: pollution by

2.1. Crushing The ore is stockpiled and the process begins by feeding the ore into a hopper with a loader. The ore is then drawn via a variable speed hydraulically driven belt feeder and delivered to the crusher. Crushing is carried out in a jaw crusher. Crushed ore is conveyed directly into the ball mill. 2.2. Grinding and sizing

OPP: Ore Preparation Plants Explained Oil Sands Magazine

2016年4月24日 The crushed ore is dumped onto conveyors, which transport the loose oil sands to a storage pile or surge bin. Since the oil sands ore is mined out of a pit (or hole in the ground), the crushing plant is normally also installed at a lower elevation, or in-pit. This helps minimize elevation changes for the haul trucks.

(PDF) SIZE REDUCTION BY CRUSHING

2017年3月4日 Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by...

Technology improvements of crushing process in

1996年3月1日 1. Introduction Based on detailed laboratory and industrial research, Majdanpek Copper Mine makes the reconstruction and the modernization of crushing plant in order to create the adequate conditions for profitable business. Studying the operation efficiency of each crusher, numerous investigations are made.

11.24 Metallic Minerals Processing US EPA

2015年9月10日 Metallic mineral processing typically involves the mining of ore from either open pit orunderground mines; the crushing and grinding of ore; the separation of valuable minerals from matrixrock through various concentration steps; and at some operations, the drying, calcining, or pelletizingof concentrates to ease further handling and refining.

Mining and processing plant engineering design ESFC

2022年8月14日 The obvious advantage of this equipment is the fine, uniform crushing of the ore. The disadvantages of the disintegrator include the rapid wear of pins, the difficulty of replacing them and the need for accurate balancing of the rotating parts of the machine. Engineering design of grinding equipment After the crushing process, the ore is ground.

Major MinesProjects Veladero Mine

Ore that has a gold grade above the cut-off grade for crushed ore is trucked from the mine or stockpiles and crushed in one of two two-stage crushing circuits to a nominal size of 80% passing (P80) 40 mm. The crushed ore is hauled by a fleet of 11 trucks from the crushing plant to the VLF, a distance of approximately 4.2 km.

مطحنة الجادة yarraville

يستخدم الذهب في صنع الحلي وادوات الزينه

كيفية إنشاء مطحنة الحجر

آسیاب توپ آسیاب خانگی هند

آلة تصنيع مسحوق التلك

شركة المحاجر الجرانيت في نigeria

محجر تكسير مصنعي الحجر في مصر

مصانع استخلاص خام الحديد في الولايات المتحدة

كسارة الحجر الهند الجنوبية

خط التعدين في دهرادون

الشركات السعودية التي تستورد معدات ثقيلة من امريكا

حزام ناقل crus

إصلاح الكسارة الفحم في إندونيسيا فيديو

إثراء مصنع المنغنيز 7c خام الحديد إثراء المعدات

هيلتي تكلفة مطحنة الخرسانة بلا غبار

کنترل پنل سیمان آسیاب

آلة تصنيع البلوك المستعملة في المملكة المتحدة للبيع

بعد غربل غربالي زين عرب واجد طاحو ما العين

بدء تشغيل نظام التشغيل وحدة طحن الأسمنت

سحق الحجارة في هلوهلوي

مطاحن ديامانت مولينز

zg pe 500 times 750 كسارة

اختيار المعدات للتعدين على نطاق صغير

دراسة عن الرماد المتطاير النض السائل يستخدم لإزالة الكبريت غاز المداخن

عملية تصنيع الكلنكر في روركيلا مصر

المورد مطاحن الكرة من المملكة العربية السعودية

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20